Specializing in the design and manufacture of active implantable medical devices (AIMD) under contract, Cisteo Medical relies on cutting-edge technology to ensure the laser welding and sealing of implantable titanium housings , used for example in neurostimulation or cardiac stimulation .

The principle of laser welding is to bring energy to the junction of two parts so that they melt and weld. Generated by a laser beam, the energy is concentrated in a single point and the fusion is thus carried out very locally, which avoids overheating of the entire component. No deformation is to be deplored since only the welding area is affected. To obtain a watertight weld, several successive welding points overlap and create a bead.

This process works without the addition of material and therefore has no impact on biocompatibility . Note that laser welding can be carried out on different materials: stainless steel, titanium, titanium alloys, etc.

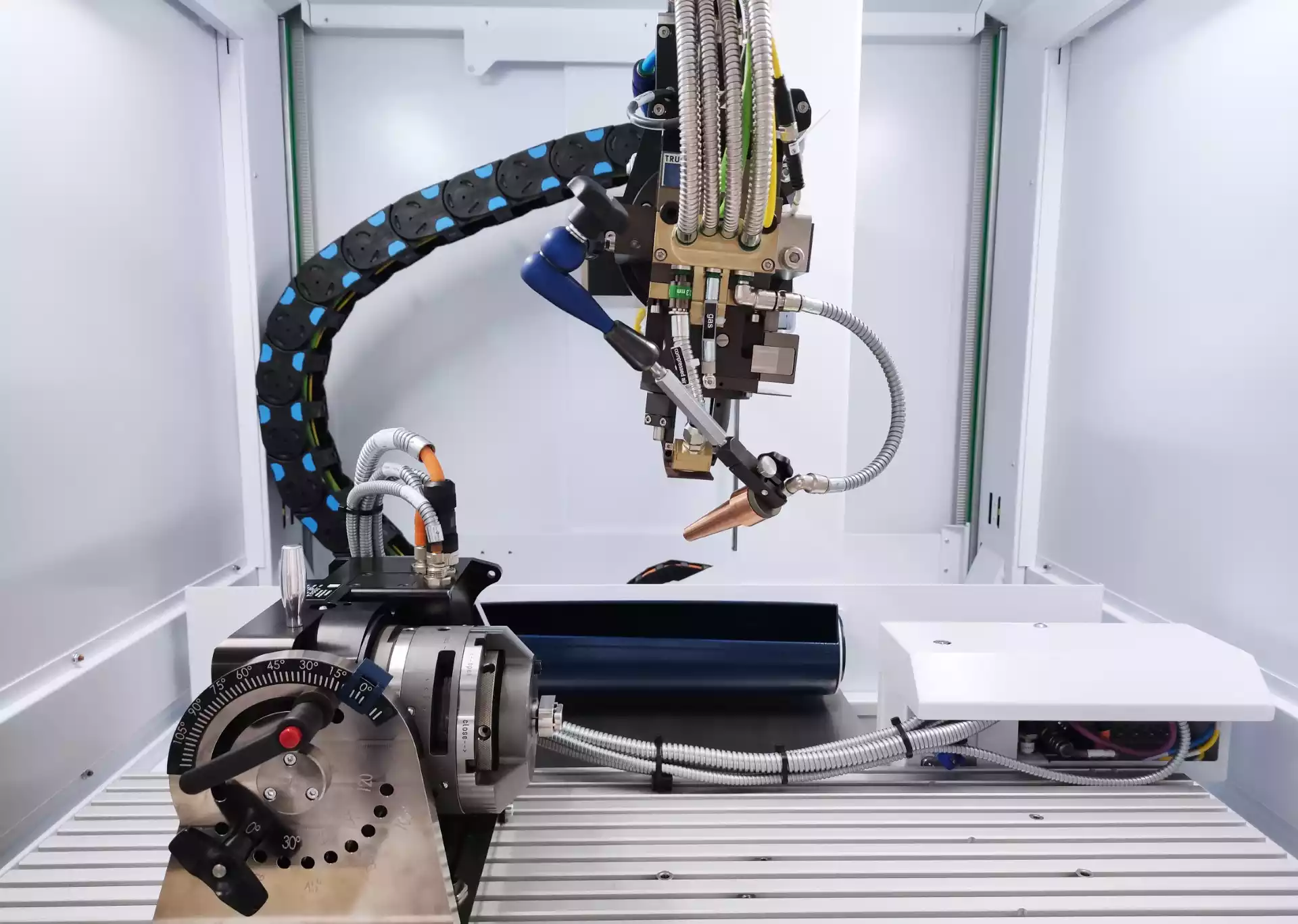

To guarantee a reliable and repeatable solution, Cisteo Medical has integrated a 5-axis laser welding system in its cleanroom. This can be used for rotary, flat or complex trajectory welding.

The machine moves along 5 automated axes and one manual axis: in addition to the X, Y and Z axes, a chuck rotates and the laser beam head pivots on itself. Coupled with a spacious work area, this dexterity enables the welding of complex implantable titanium housings.

Thanks to the flexibility of this installation, it is possible to produce quantities ranging from a few prototypes to large series, while maintaining the same repeatability . Producing prototypes as close as possible to the final device makes it possible to remove many technical obstacles in the very early phases.

With laser power of up to 2 kW, flexible weld geometries and high weld depths are easily achieved, an important criterion for ensuring mechanical strength and tensile strength of the part, for example. In addition , welding under inert gas limits oxidation of components as well as intermediate storage in a dry cabinet .

The boxes are closed in two stages:

Whether it is a neurostimulator, a pacemaker or monitoring, the use of a sealed titanium housing makes it possible to embed electronic components capable of acting on a pathology or transmitting information to the patient or the medical team. However, this implementation requires imperative hermeticity of this housing.

The welding ends with a series of operations designed to ensure the durability of the product by protecting the internal electronic circuits from oxidation and to check the tightness of the DMIA.

Governed by military standards MIL-STD-202G Method 112E and MIL-STD883J Method 1014-14, these tests involve filling the case with helium or argon, depending on the sensitivity of the components to helium. In the case of helium filling, a leak test is applied directly to the part. If the case has been filled with argon, it first undergoes a "bombing" operation, i.e. it is placed in a box filled with pressurized helium; if the helium has been able to penetrate the case, it will also be able to escape during the leak test.

The helium fine leak test is performed using a mass spectrometer that observes the composition of the particles escaping from the housing. A large leak test by immersion in a liquid is also conducted to verify that the helium has not completely escaped beforehand. These operations are concluded by routine visual and dimensional checks.

Before production starts, a process validation is carried out. It also includes coverage tests and metallographic cuts.

If you'd like to find out more about the inert gas laser welding process, please don't hesitate to contact us.

We can carry out a series of tests to define the most appropriate process for your requirements, as well as prototypes.

We would be delighted to discuss this with you.